Eye Drop Packaging

View Reviews

Home

Health Boxes

Custom Eyelash Boxes

You agree to our Privacy Policy by submitting this quote form!

Reliable Production

Our One Step Custom Boxes team specializes in creating unique and stunning packaging designs that will leave your customers in awe. Their need could be anything from the material and size to printing and finishing touches. Our flexible options can be tailored to match your brand’s vision and graphic and also provide business eco-friendly solutions or premium finishes depending on what you need.

| Dimensions | Customization Options |

|---|---|

| Printing | CMYK, PMS, No Printing, Pantone Colour |

| Card Stock | 10pt to 28pt (60lb to 400lb) ArtCard, SBS White Bleach Card, Eco-Friendly Kraft, 2mm E-flute, 3mm E-Flute , corrugated Bux Board, cardstock |

| Quantities | 100 – 100,000 |

| Coating | Gloss Lamination , Matte Lamination, Spot UV |

| Other Procedure | Die Cutting, Gluing, Perforation, Digital Printing |

| Other Options | Custom Window Cut Out, Gold/Silver Metallic Foiling, Embossing, Debossing, Raised Ink, PVC Sheet. |

| Digital Proof | 3D Mock-up, Physical Sampling (On request) |

| Turnaround Time | 10, 12 Working Days, Urgent Also available |

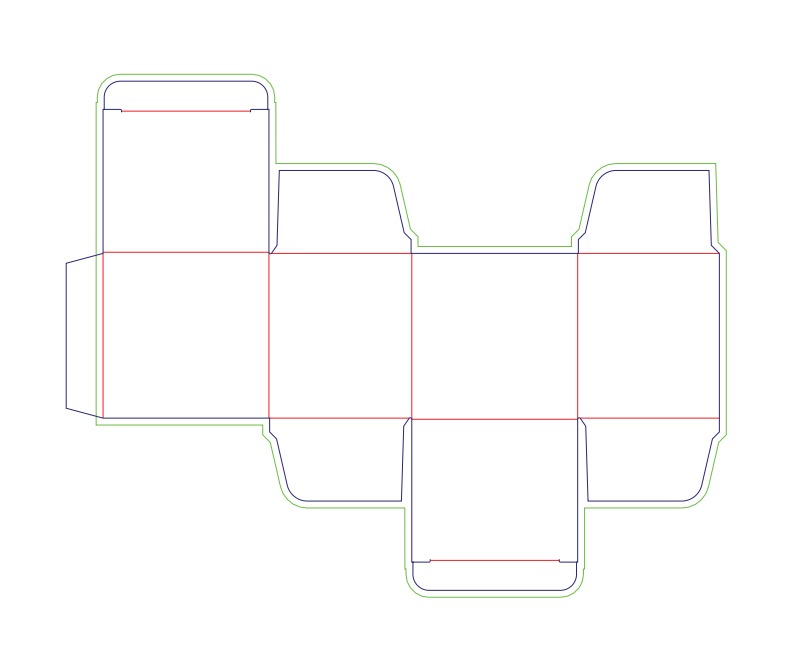

Artwork Preparation Guide

Use our artwork guidelines and the directions below to prepare your artwork files for publication. Need a hand preparing your artwork? We can help. We offer 100% free design support and mockups to ensure the style of the final product perfectly matches your vision. Simply contact our packaging wizards—we’re just a call or click away!

Cut Line (Black Lines)

The cut line (black lines) indicates the cut's ultimate size. Important artwork and text should be positioned at least 0.125 inches within the cut line.

Bleed Line (Green Lines)

Green lines indicate where the bleed line is located. To provide a smooth print, any artwork that crosses the cut line should be extended to the bleed line.

Crease Line (Red Lines)

The crease line (red lines) indicates where the product should be folded.

Perforation (Dotted Black Lines)

Perforation (dotted black lines) refers to paper punctured with tiny holes for easy tear and fold.

Safety Margin (Dotted Green Lines)

The safety margin (dotted green lines) indicates where artwork and text can be securely put within. Unless your design is purposeful, all artwork should be at least 0.125 inches

01

Choose your custom packaging

We have a collection of retail packaging boxes, which have been put together with much detail, so you can pick the most suitable one for your venture. As you browse for custom boxes, our proactive staff will be ready to support any of your concerns. All you have to do is use the Live Chat Support tool that is on the bottom right side of your screen, which will let you see and communicate on the chat box while doing other activities at hand.

02

Request a Free Quote

It is easy, fast, and most importantly free to ask for a quote from us. Simply fill out the form within this page, located in the top right corner, and type your requirements. Do note to give important pieces of information like the preferred size of the box, quantity needed, design ideas, personal wishes, as well as deadlines for the project.

03

Don’t Forget to Place Your Order

Our quotation specialists will get to work as soon as you place your order. We aim to respond to your inquiries within 1-2 hours, and we can promise packaging work will commence almost instantaneously. If you need assistance in design during your estimation request, feel free to provide us with your contact details so that our dedicated design consultant can reach out and assist further.

04

Invoice and DieLine Design

A packaging dieline is a blueprint for your box design, making sure the art for your packaging is produced after the details have been finalized. It’s a flat drawing and as the name suggests, it contains outlines of marks that indicate where the package will be cut and folded. We will send you the artwork for review within one or two business days after receiving your payment. Our dieline will be created based on the information filed in the dieline order form.

05

Get Creative with Digital Proof

To prepare your template, we will create a new dieline file and attach your Digital Proof of artwork to it. As such, please take care to make sure that your initial designs meet our guidelines on templates so that we can incorporate the art into the template. These parts have to be done before your artwork file’s mass production, hence we need to make sure proper parameters (color, font size and type, images) and formats will be adopted.

06

Receive a Product Right at Home

After placing the order and providing digital confirmation, an email will be sent to you. It will specify the production department. A maximum of 10 to 12 business days after, the package will be waiting at your door. There will not be any customs or handling charges either.

Worldwide Satisfied Brands

Our customers always believe that we provide them with the best service. Whether it’s regarding Prices or quality, we never compromise on it. Because our vision is to make you our long-term customer, we want to become a one-stop partner where we can provide all printing services in one place without any worries about production.

More Than +5000 Satisfied Clients Worldwide

Create Custom Boxes Quick and Easy!

- Minimum 100 Boxes

- Free Die and Plates

- Competitive Pricing

- Customized Sizes & Styles

- Fast Turnaround Times

- High Quality Offset Printing

- Free Design Support

- Free Shipping

Reviews From Happy Customers!

I received highly reliable and efficient services, and my packaging was delivered on time, with outstanding packaging boxes for my business.

George Bangs

The experts are too cooperative and create lavish designs with the latest techniques. My experience is fantastic because I turned my dreams come true.

Henry Vance

I want effective and unique boxes that present my small business’s luxury and durability. I get exactly boxes that enhance my customer experience.

James Flint

I am inspired by high-quality packaging that remains durable while transiting and shipping without damage. This makes me a fan of One Step Boxes

Charles Briggs

Anti-scratch lamination

Laminated BOPP film that’s scrape, clang, and point-resistant. Cost-effective option.

Aqueous coating

Clear, presto-drying, water-ground, and eco-friendly coating. Available in buff or matte finish.

Velvet lamination

The laminated defensive film adheres to the face of packaging accoutrements to maximise continuity.

Matte lamination

Matte refers to a non-glossy, smooth finish that reduces reflections, giving surfaces like paper or packaging a soft, elegant, and understated appearance.

flat spot UV gloss

Fast-drying coating cured with ultraviolet light. Available in buff or matte finish.

Soft Touch Skill Lamination

Soft to the touch lamination analogous to peach skin. Accessible in a satin or matte finish.

Embossed Spot UV

UV coating is used on the prescribed area and cured using ultraviolet radiation

Digital print

Digital printing system that requires no printing plate. Designs are made electronically, making them cost-effective for small runs.

Offset Print

High-quality printing system that utilises a printing plate and rubber mask to transfer designs on paper. Stylish for large runs.

Soy-based ink

100% eco-friendly and comprised of soybean/vegetable oil painting and color to give a vibrant colour affair.

Pantone colour

Pure colour grounded on specific ink formulas to consistently and precisely print colour.

Water-base ink

Comprised of water and colour that provides a high-quality colour affair and is 100% eco-friendly.

Pantone Metallic

Metallic colour grounded on specific essay formulas to consistently and precisely print colour.

Blind Ddbossing

Form of printing in which a die is pressed on the front of the material to create a raised effect.

Blind Embossing

Form of printing in which a die is pressed on the reverse side of the material to create a raised effect.

Textured paper

Non-eco-friendly ink comprised of oil painting and colour that provides a high-quality color affair.

Holographic Foiling

It creates a striking, reflective effect, adding a decorative and eye-catching touch to packaging and printed materials.

Hot Foil stamping

Form of relief printing in which antipode is transferred to a face at high temperatures.

Registered Embossing

Form of printing in which a die is pressed on the reverse side of the material to create a raised effect.

Varnish

The clear coating, applied using the CMYK printing system. Available in buff, satin, or matte.

Grounded Texture

I am inspired by high-quality durable packaging while transiting and shipping without damage. This makes me a fan of One Step Boxes

Ready to think outside the box? Let's get started!

Contact a custom packaging specialist for a free consultation and instant price quote. Get Free Quote